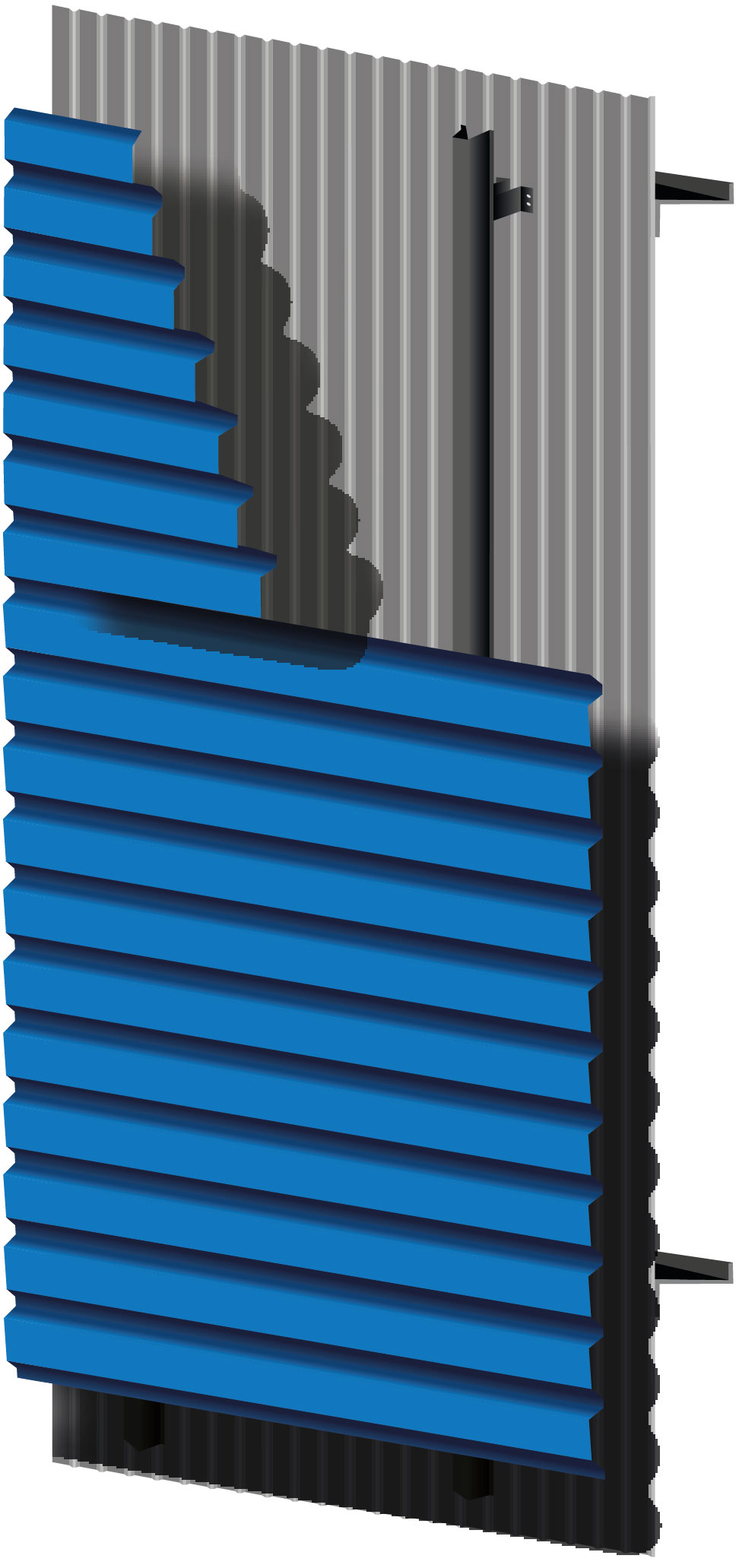

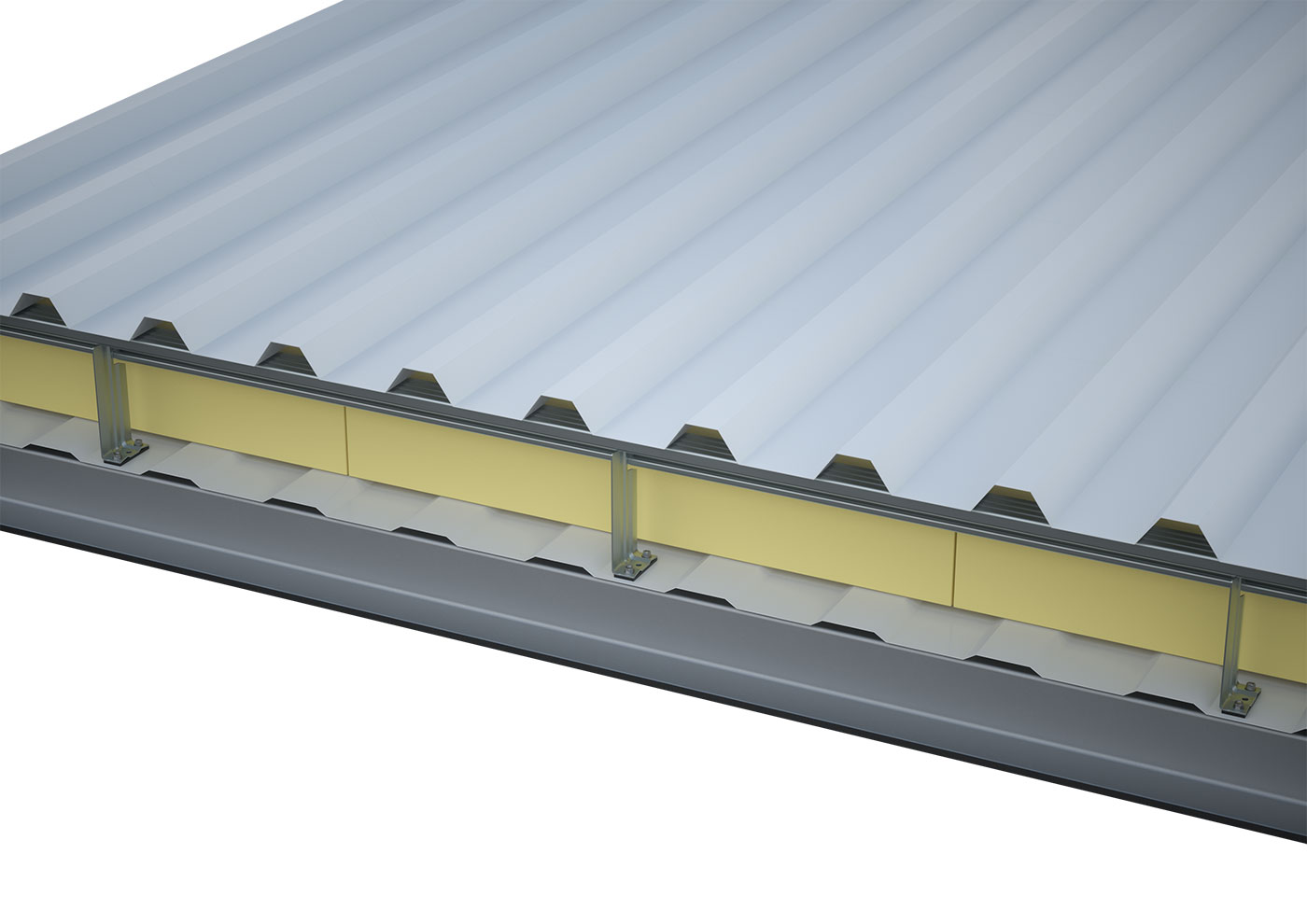

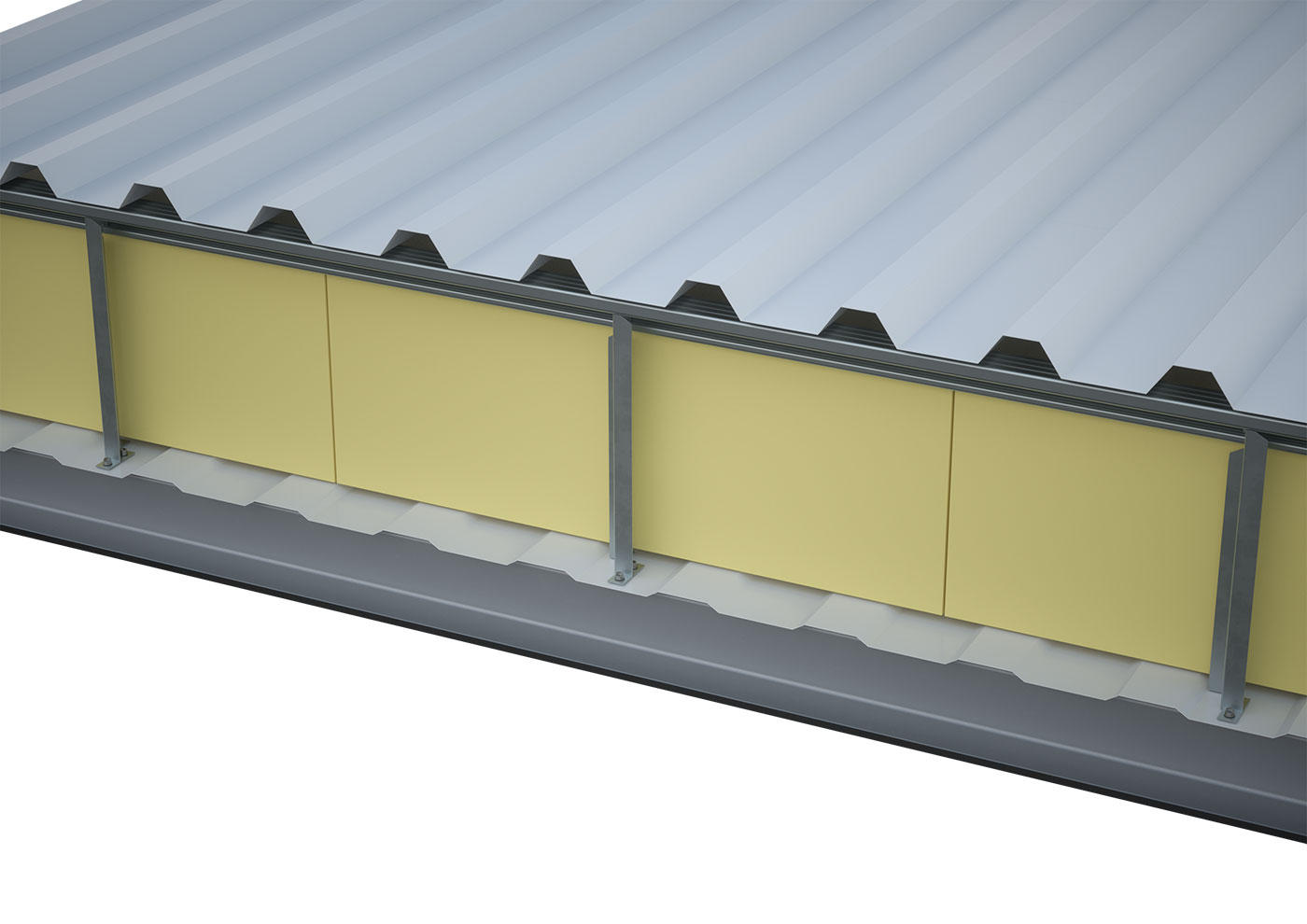

For all new build and refurbishment applications Gridtite is a long established, class leading spacer system with a proven track record. Tested extensively by independent laboratories and supported by a full technical package. Gridtite is ideal for roofing and wall cladding where the spacer system runs horizontally* across the wall or roof, supporting ‘top to bottom’ sheeting.

Gridtite is a lightweight bar and bracket system that is designed to provide a controlled space between the inner and outer metal sheets that make up “twin skin” site assembled roofing and walling systems. Insulation goes into this space – usually either a glass fibre or rock fibre quilt.

Gridtite is easy to install, strong and stable when sheeted over; is durable and easy to relocate or alter if the need arises. It is easy for self-drilling fasteners to drill into, but provides good fastener grip to resist pull-out loads. Gridtite has very little effect on the thermal performance of the insulation, which assists the building in complying with Part L of the building regulations. COSHH and product data sheets are available for downloading here.

* for wall sheeting that runs horizontally, use Gridtite GP.

-

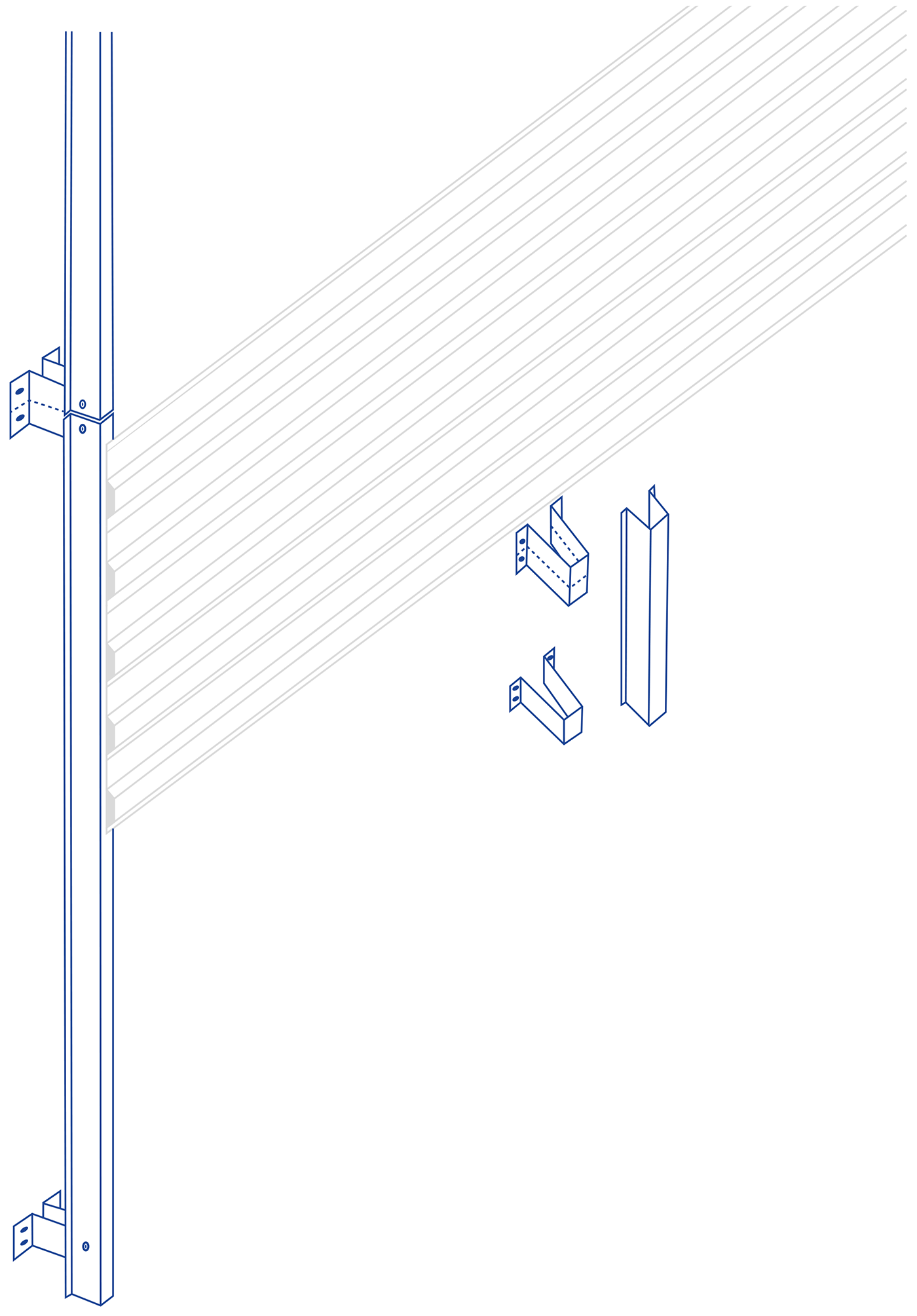

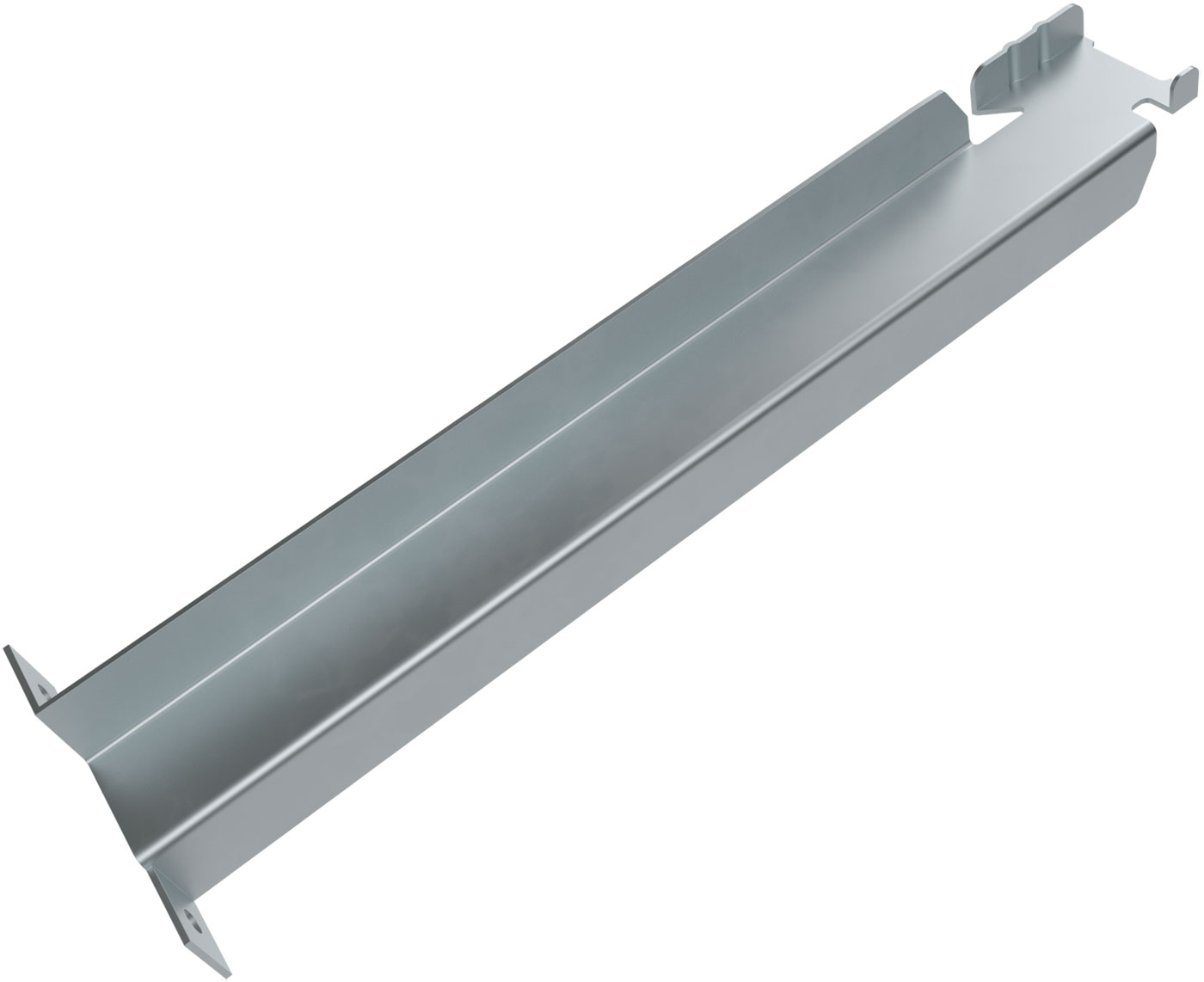

Bracket

Manufactured from 1.55mm high tensile galvanised steel to BS EN 10346-S390+Z275 incorporating stiffening ribs and vapour seal pad/thermal insulator.

Heights available 60–220mm generally in 10mm increments. Other heights can be produced by arrangement.

Brackets are boxed in varying quantities depending upon size; every box features simple, pictorial fitting instructions.

-

Ultra Bracket

Due to thermal performance requirements, the depth of insulation specified has increased over the years. With this in mind Fixing Point have designed and developed our new Ultra Bracket.

The improved design adds strength & stability to the bracket which allows for depths of up to 400mm without the need for additional support brackets.

Manufactured from 1.55mm high tensile galvanised steel to BS EN 10346-S450+Z275.

Heights avaialable: 140 – 400mm generally in 10mm increments.

Brackets are boxed in varying quantities depending upon size; every box features simple, pictorial fitting instructions.

-

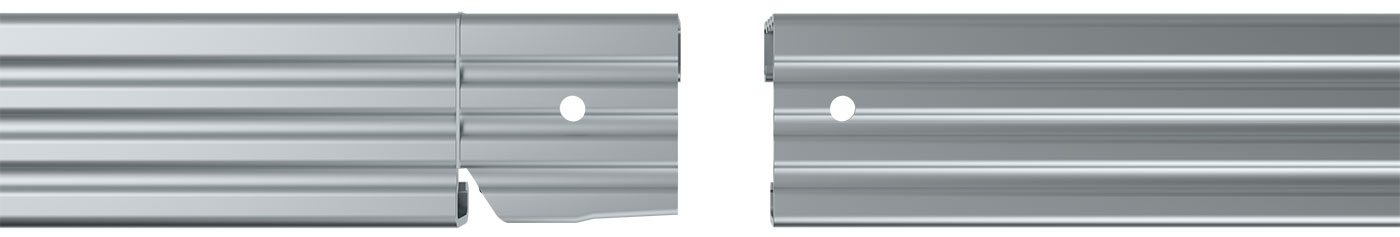

Bar

Manufactured from 1.25mm high tensile hot-dip galvanised steel to BS EN – 10346-S390GD+Z275 incorporating a 40mm spigot end for easy on-site connection to form a continuous level support.

Corrugations along its length give strength, stiffness and optimum screw pull out performance.

Lengths 1, 2, 3 & 3.6m (effective cover). Bar weight = 1kg/m.

The bar length we quote is the finished ‘fitted’ length and ignores the 40mm joint. A pre-punched hole in both ends allows accurate alignment and, by inserting a fastener, a means to lock the lengths together in a more positive manner than a punched tab.